CNC Machining Service

Zhengda CNC machining capabilities

On-demand CNC machining for rapid prototyping and production parts, experienced and thoroughly vetted Zhengda CNC machine shops.

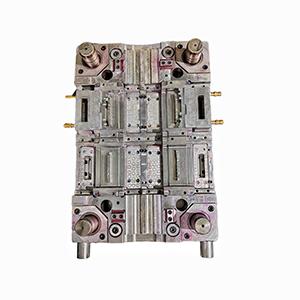

We operate almost every kind of CNC mill and turning center, and pride ourselves on being able to machine whatever you need, from simple, ‘as-machined’ workholdings to complex, organic geometries with tight tolerances. On request, we can also produce parts with EDM and grinders. Build envelopes, minimum feature sizes and design guidelines vary for milling and turning.

CNC Milling Service

Acording the customer’s CAD files, receive an instant CNC milling quote in 24 hours.

CNC Turning Service

Acording the customer’s CAD files, receive an instant CNC turning quote in 24 hours.

Zhengda CNC milling service capabilities

From prototyping to full production runs. Our 3 axis, 3+2 axis and full 5-axis milling centers will allow you to produce highly accurate and quality parts to meet even your most stringent requirements.

What is CNC Machine Service?

CNC stands for Computer Numerical Control, which refers to a machine controlled by a computer program. CNC machines are used for various tasks, including cutting, drilling, milling, and turning.

CNC machine services involve using these machines to perform highly accurate and repeatable precision tasks. These services are often used in manufacturing, requiring precise and consistent parts.

To use a CNC machine, a program is first created using computer-aided design (CAD) software. The program is then uploaded to the machine, which uses the instructions to perform the desired operation on a piece of material.

CNC machines can be used with various materials, including metal, plastic, wood, and composites. They offer many benefits, including faster production times, higher accuracy, and the ability to create complex shapes and features.