Medical Industry and Plastic Injection Molding

Medical Industry and plastic injection molding

plastic injection molding is widely used in the medical industry to produce a variety of medical devices and components. The process of plastic injection molding allows for the production of complex shapes with high precision and accuracy, making it an ideal manufacturing method for many medical applications. Here are some of the ways plastic injection molding is used in the medical industry:

Medical devices: Plastic injection molding produces various medical devices. These devices often require high precision and accuracy, and plastic injection molding can meet these requirements.

Laboratory equipment: Plastic injection molding produces pipettes, microplates, and test tubes. These components require high precision and accuracy to ensure reliable results.

Packaging: Plastic injection molding is used to produce packaging for medical devices, including sterile barrier systems and custom packaging for individual products. These packaging solutions can help maintain the medical device’s sterility and integrity.

Why Choose Zhengda Mold To Be Your Mold Expert In Medical Fields

1. ISO certificated standard

Zhengda mold is ISO certified, FDA approved, and we provide our customers with guaranteed medical injection molded products with a clean and sanitary injection molding workshop and strict quality control to ensure the quality of our customers' products.

2. Mature Customized Design

We offer mold design services for your special plastic medical product needs. Our engineering designers have been rooted in the mold design industry for 20 years and have the expertise and experience to provide you with the best solution and save you money.

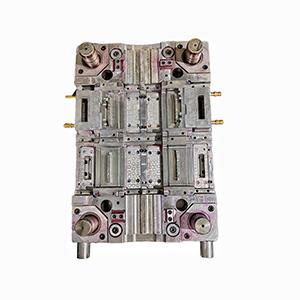

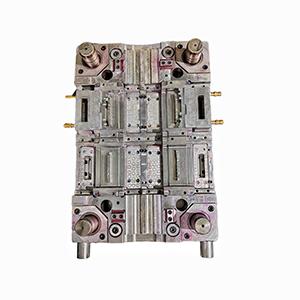

3. Advanced Equipment

With the help of mirror image spark machines, high speed CNC, 3D precision manufacturing and measurement equipment, medical parts are monitored and verified from concept to machining to material selection and dimensioning for manufacturing.

4. Rigorous Quality Control & Inspection

Our medical injection molding is done in strict accordance with ISO quality assurance standards. All plastic materials have biocompatibility reports and their colors are medically certified. Finished products undergo rigorous inspection before delivery.

5. Medical grade plastic available

Medical parts require high material requirements, but we can provide you with medical-grade plastic materials and relevant certificates. At the same time, we have been working with the medical industry for 20 years and have a good grasp of medical injection molding materials and experience, so we can recommend good materials for our customers to save their time.

6. Complete secondary processing service

The surface of injection molded products requires good appearance, such as texture, screen printing, mirror polishing, etc. We can achieve all these surface treatment requirements from our customers. We also have a professional assembly department for some medical parts assembly, aiming to provide satisfactory service to our customers.