TWO-SHOT injection moldING PART DESIGN

From the very beginning, our customers enjoy the advantage of a 2-4 week lead-time reduction for tooling as all injection molding Part Design and Tooling is performed in-house. This includes all molds, trim tools, and fixturing.

As a Tier 1 and Tier 2 supplier, we are comfortable being 100% design responsible or serving as a design partner. Our company is Horizontally Integrated, giving us the upper hand when it comes to determining material and process constraints and limitations, as well as the confidence to stand behind our work.

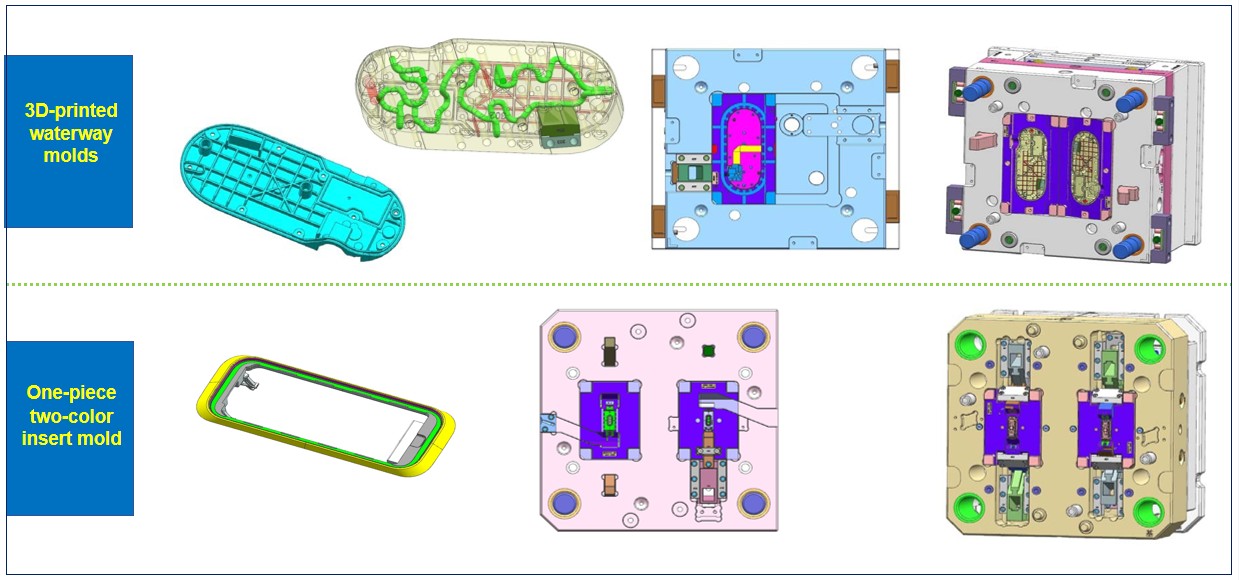

Two-Shot Injection Mold Design & Prototyping

Speed is everything; whether you need parts in less than 24 hours or in a week, we have the in-house resources needed to meet your deadline.

Depending on your need, we can produce tooling from wood, epoxy, aluminum, and steel to produce parts for appearance evaluation and physical testing.

We can develop tooling for prototype and production injection molds, assembly and test fixtures, and end of arm for robotic applications.

Post time:Sep-25-2020