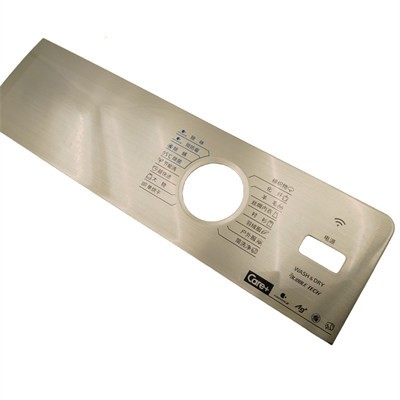

Secondary Process Of Plastic Injection Molding

A Full Suite of Professional Finishing Services

We not only make plastic parts for customers, but also provide customers with a complete set of services, from mold design to product molding, to secondary processing of products. We are committed to providing customers with products with perfect appearance and high quality. So we provide a complete set of surface treatment services.

- Silk printing

- Electroplating

- Sandblasting

- Laser engraving

- Polishing

- Painting

- Texture/Matte

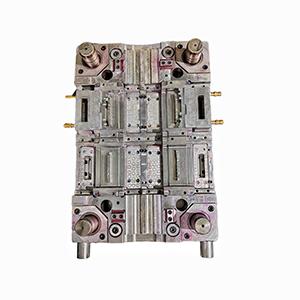

Accurate and Efficient Assembly

Zhengda mold provides assembly services for your plastic parts as part of our secondary processing services. To provide customers with convenient services, from production to assembly to product surface treatment services, we will do it for you.