Professional Team Providing Environmentally Friendly, High-Quality Products to Meet Customer Needs.

Mold Department

Mold Department

We utilize PRO/E, UG, and MOLD FLOW for product and mold design, along with UG MANUFACTURING for designing machining paths and manufacturing mold components. Mold design adheres to HASCO, DME, and LKM standards according to customer requirements.

Upon approval, mold drawings are handed over to mold process engineers for process arrangement, where special machining processes and methods are planned. Manufacturing and assembly of each component take place in the mold workshop, ensuring precision through various high-precision equipment.

injection molding Department

injection molding Department

Our company's injection molding machines feature brands such as Haitian, Changfei Ya, Fanuc, and Arburg, known for their high precision, stable product quality, and efficient production. These machines represent mid-to-high-end equipment within the injection molding industry. Equipped with imported robotic equipment such as Xin and Weimeng, our machines utilize five-axis servo mechanical arms with a gripping force of 5kg. They can cater to a wide range of high-end acoustic products including exterior components, interior components, and module assemblies. With an experienced and exceptional injection molding technical team in the industry, we efficiently address various technical issues associated with different types of products, ensuring outstanding product quality.

Pad Printing Department

Pad Printing Department

We possess 43 high-precision single-color pad printing machines, 1 high-precision dual-color pad printing machine, 1 flat and curved surface screen printing machine, and 10 precision hand-printing stations. Our pad printing series employs environmentally friendly ink cups, ensuring comprehensive assurance of print quality.

The workshop adopts a streamlined management model for operations, emphasizing energy efficiency, high precision, and high yield in pad printing and screen printing processes. This facilitates multi-color registration printing for products with multiple stations in a single operation. We also have a UV production line for products with special requirements, allowing UV printing on surfaces according to customer specifications. Additionally, we have high-precision ultrasonic welding equipment for assembling and welding plastic products.

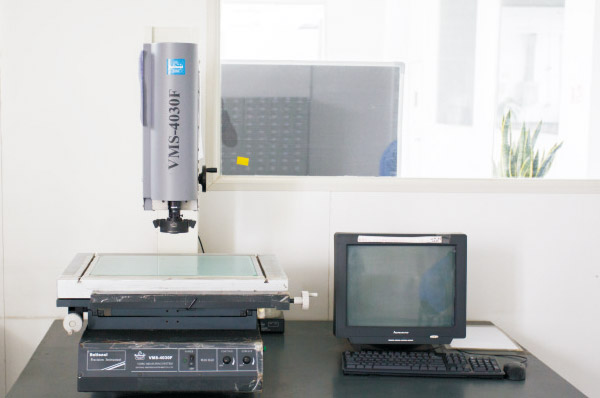

Quality Control Department

Quality Control Department

Our primary inspection and testing equipment include Coordinate Measuring Machines (CMM), Optical Comparators, Profile Projectors, 2D Height Gauges, Rockwell Hardness Testers, Shore Hardness Testers, Melt Flow Index Testers, Impact Testing Machines, Microcomputer-controlled Universal Testing Machines, Digital Pendulum Impact Testing Machines, Energy Dispersive X-ray (EDX) Analyzers, RCA Abrasion Testers, Abrasion Testers, Capacitance/Inductance Meters, Rapid Moisture Analyzers, Energy-Dispersive X-ray Fluorescence Spectrometers, Three-Box Thermal Shock Test Chambers, High and Low-Temperature Alternating Humidity Test Chambers, Salt Spray Test Chambers, etc.

Post time:Sep-25-2020