Consumer electronics

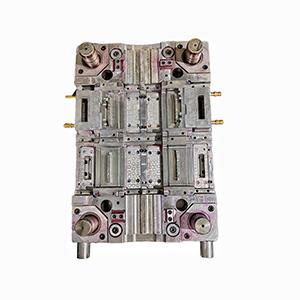

injection molded Electronic Component Capabilities

As specialists in the mass production of injection molded parts for the electronics and telecommunications industry, we create plastic injection molded electronic components:

· Charging head housing

· Wall Switch panel

· In wall box

· Game controller housing

· E-cigarette case

· Intelligent Remote controller housing

· battery caps and enclosures

Materials commonly used for precision electronic component injection molding include:

· ABS (acrylonitrile-butadiene-styrene)

· PC (Polycarbonate)

· TPU (Thermoplastic urethane)

· PA (Nylon)

· HDPE (Polyethylene)

· PP (Polypropylene)

Why Choose Us

As your partner, we can use advanced technology and manufacturing process to provide better quality and better appearance spare parts for the electronics industry.

ISO 9001:2015 certificate

We own strict project management flow from material selection to part inspection to ensure the product quality.

Powerful Design Capability

Advanced mold simulation and analytical design help ensure that every product we produce is optimally functional and cost-effective.

Inclusive Secondary Services

Alpien mold provice one stop services, like surface treatment and product assembly, create the perfect surface for your product.

Experienced Engineers

10+ years engineers in mold industry, our engineers know about your needs and give best deisgn scheme.