-

-

ZHENGDA MOLD MAKING SERVICE

Mold making is a high precision process that requires a high level of skill process and rich skill and experience to save your cost [ .. ]Read More -

ZHENGDA INJECTION MOLDING SERVICE

Zhengda is specialized in plastic injection mold tolling and injection molding service with more than 30 years experience [ .. ]Read More -

ZHENGDA SECONDARY PROCESS

Zhengda provide a complete set of surface treatment services, from mold design to product molding, to secondary processing of products. [ .. ]Read More

Looking for a quality plastic injection molding parts?

WE ARE WORLDWIDE

Weifang Zhengda Industrial Co., Ltd. was founded in 1996, located in the world kite capital of Weifang City, Shandong Province, Shandong surveying and mapping geographic information industrial park, registered capital of 34.86 million yuan, is a mold design and development with 600+ manpower and injection molding production, sales and service in one of the high-tech enterprises. With a construction area of more than 40,000 square meters. It has standard workshop, equipped with domestic leading production and processing equipment.

The company focuses on the production and processing of precision electronic parts, mainly used in headset, VR/AR, smart wearable, smart speaker, smart home, auto parts and other high-tech products, our main customer is Goertek, The final customers are Apple, Huawei, Amazon, Google, HP, Samsung, SONY, Byte, Foxconn, Xiaomi and other leading consumer trend of cutting-edge brand companies.

mark01mark02mark03mark04

mark01mark02mark03mark04 -

28

Years

Of Experience -

500+

Successfull project

with client's satisfication -

7

Countries

we have exported to -

100

D & B

Certificate

What We Do

MANUFACTURERS OF PLASTIC INJECTION MOLD AND PLASTIC INJECTION MOLDING PARTSHOW WE WORK

- 1

FIELD OF WORK

- 2

EXPERIENCE And Expertise

- 3

GO Hand In Hand

MOLD DESIGN

Zhengda design moulds since 1996, that we meet specific customer requirements. Zhengda provides top notch engineering services by combining proven design standards with the most modern techniques available today for designing and manufacturing plastic injection molded parts.

We have qualified designers with very good experience in design software & mould designing. They are working by coordinating with tool room & moulding shop. So we take pride in designing plastic injection moulds for small to medium sized parts that are used in the medical, electrical, electronic, automotive, aviation, connector, consumer product, textile and industrial fields.

Zhengda engineers offer plastic design assistance and become a valuable extension of your product development team. Zhengda helps to design your product with tool building, material selection, and part manufacture in mind to help control cost and prevent problems before they arise.

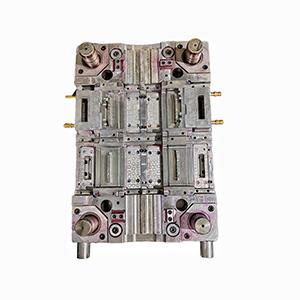

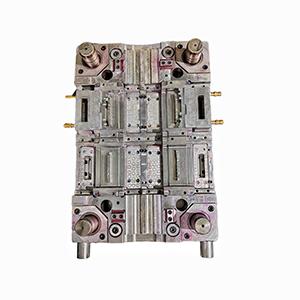

MOLD MAKING

Injection molding is one of the most common manufacturing processes used to produce plastic goods. It is a high-demand process that can reproduce the same part thousands of times. The process starts with a Computer Aided Design (CAD) file that contains a digital copy of the part. The CAD file is then used as a set of instructions to aid in the mold manufacturing process. The mold, or tool, is typically made from two pieces of metal. A cavity in the shape of the part is cut into each side of the mold. This mold is usually made from aluminum, steel, or an alloy.

INJECTION MOLDING

Zhengda is specialized in plastic injection mold tooling and injection molding service with 20 years experience.We offer a complete manufacturing solution that covers every aspect of raw material verification, tool making, part fabrication, finishing, and final inspection.

Injection molding is the most cost-effective way to make a plastic part at scale. The injection molding process involves injecting molten plastic into a mold tool, then ejecting the solidified part.

SECONDARY PROCESS

As a global leader in the industry, we offer clients a full service of the products. We not only make plastic parts for customers, but also provide customers with a complete set of services, from mold design to product molding, to secondary processing of products. We are committed to providing customers with products with perfect appearance and high quality. So we provide a complete set of surface treatment services, such as: Silk printing, Electroplating, Sandblasting, Laser engraving, Polishing, Painting, Texture/Matte, etc.

QUALITY ASSRUANCE

Zhengda is an certified company. Our inspector have more than 20 years of experience in the quality inspection industry to ensure high quality during and after production.

- Supplier Quality Engineer (SQE)

- Quality Engineer (QE)

- Incoming Quality Control (IQC)

- In Put Process Quality Control (IPQC)

- Final Quality Control (FQC)

- Out Quality control (OQC)

For everyorder we receive, we can ensure the quality report list according to your requirements. Such as: DFM report, Weekly mold progress report, Mold dimension report, Full dimensional report, Material test report, Trial mold paramenter&video supplying, T1 samples inspection report, etc.

-

MOLD DESIGN

-

MOLD MAKING

-

INJECTION MOLDING

-

SECONDARY PROCESS

-

QUALITY ASSURANCE